Researchers on the Division of Power’s Oak Ridge Nationwide Laboratory have developed the primary additive manufacturing slicing pc utility to concurrently velocity and simplify digital conversion of correct, large-format three-dimensional elements in a manufacturing unit manufacturing setting.

The expertise, generally known as Slicer 2, may help widen using 3D printing for bigger objects created from metallic and composite supplies. Objects the scale of a home and past are doable, equivalent to land and aquatic automobiles and aerospace purposes that embrace elements for reusable house automobiles.

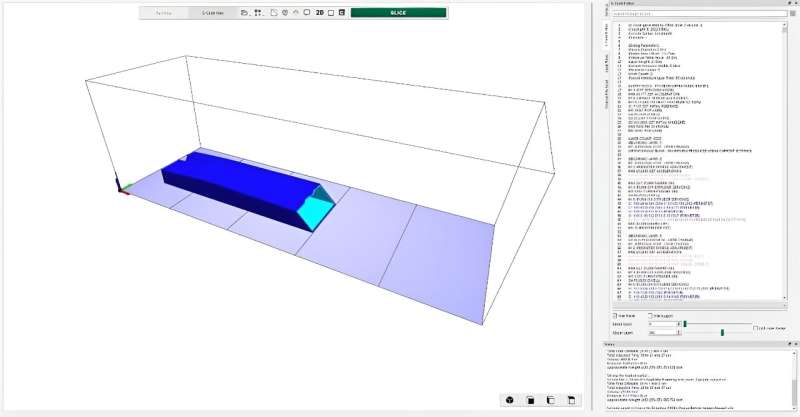

Slicing software program converts a computer-aided design, or CAD, digital mannequin right into a collection of two-dimensional layers known as slices. It calculates print parameters for every slice, equivalent to printhead path and velocity, and saves the knowledge in numerically managed pc language. The pc file incorporates directions for a 3D printer to create a exact 3D model of the picture.

“The standard of a 3D-printed object is immediately associated to the accuracy and complexity of the toolpaths that management the machine’s actions,” stated ORNL researcher Alex Roschli. “ORNL Slicer 2 software program connects immediately with varied forms of 3D printers to create an built-in platform and communicates with sensors to extend print accuracy.”

Researchers designed ORNL Slicer 2 with greater than 500 settings that management the inner construction, form, temperature and different parameters of particular person elements, layers or areas. It additionally interfaces with simulation software program that reveals complicated warmth and stress relationships through the additive manufacturing course of. The software program works with pellet thermoplastic, filament thermoplastic, thermoset, concrete, laser wire welding, MIG welding and blown-powder directed-energy deposition additive manufacturing methods.

“This connectivity interprets into improved machine instructions that enhance reliability and repeatability of the additive manufacturing course of,” stated Roschli. “The results of this software program is that additive producers can produce giant manufacturing unit elements with fewer machines and fewer price than conventional machining strategies.”

ORNL Slicer 2 is an open-source pc program out there on GitHub and utilized by greater than 50 tools producers, industrial finish customers and universities.

Quotation:

Up to date software program improves slicing for large-format 3D printing (2024, July 1)

retrieved 1 July 2024

from https://techxplore.com/information/2024-07-software-slicing-large-format-3d.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.