What simply occurred? Because the world’s main semiconductor producer, TSMC’s manufacturing halt following the 6.4-magnitude earthquake in Taiwan has triggered industry-wide concern. Its prospects are intently monitoring the corporate’s harm evaluation and potential manufacturing disruption, which might impression world chip provide chains.

The highly effective 6.4 magnitude earthquake that struck southern Taiwan on January 21 has led to a disruption in manufacturing at TSMC. Whereas there have been no reported fatalities, the tremor triggered appreciable harm all through the area, prompting the agency to implement fast security measures. TSMC evacuated employees from its central and southern manufacturing websites and quickly halted operations as a precautionary step.

Happily, preliminary inspections revealed that TSMC’s services largely withstood the quake with out main structural harm, because of their design, which accommodates seismic occasions of as much as magnitude 7.

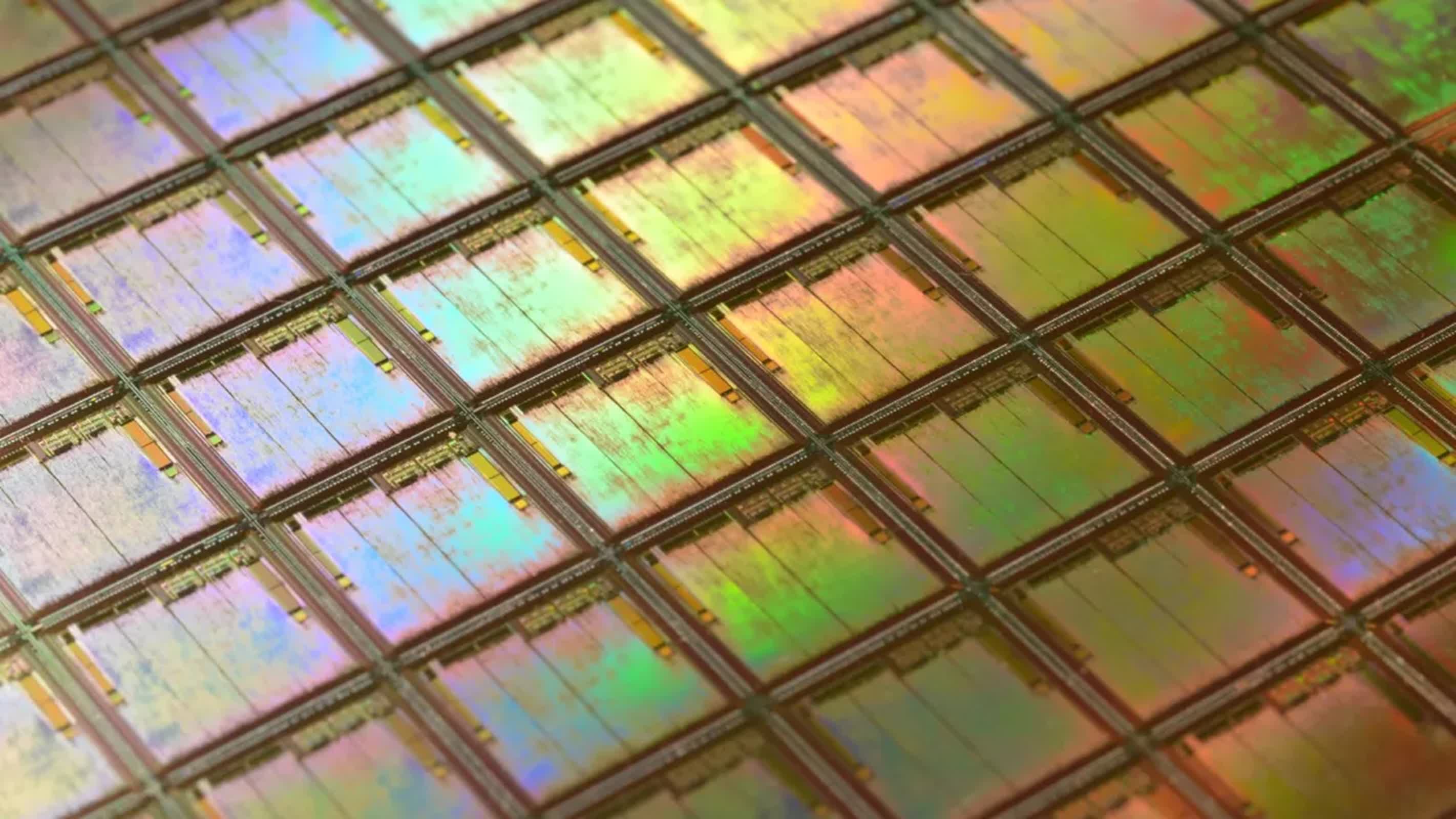

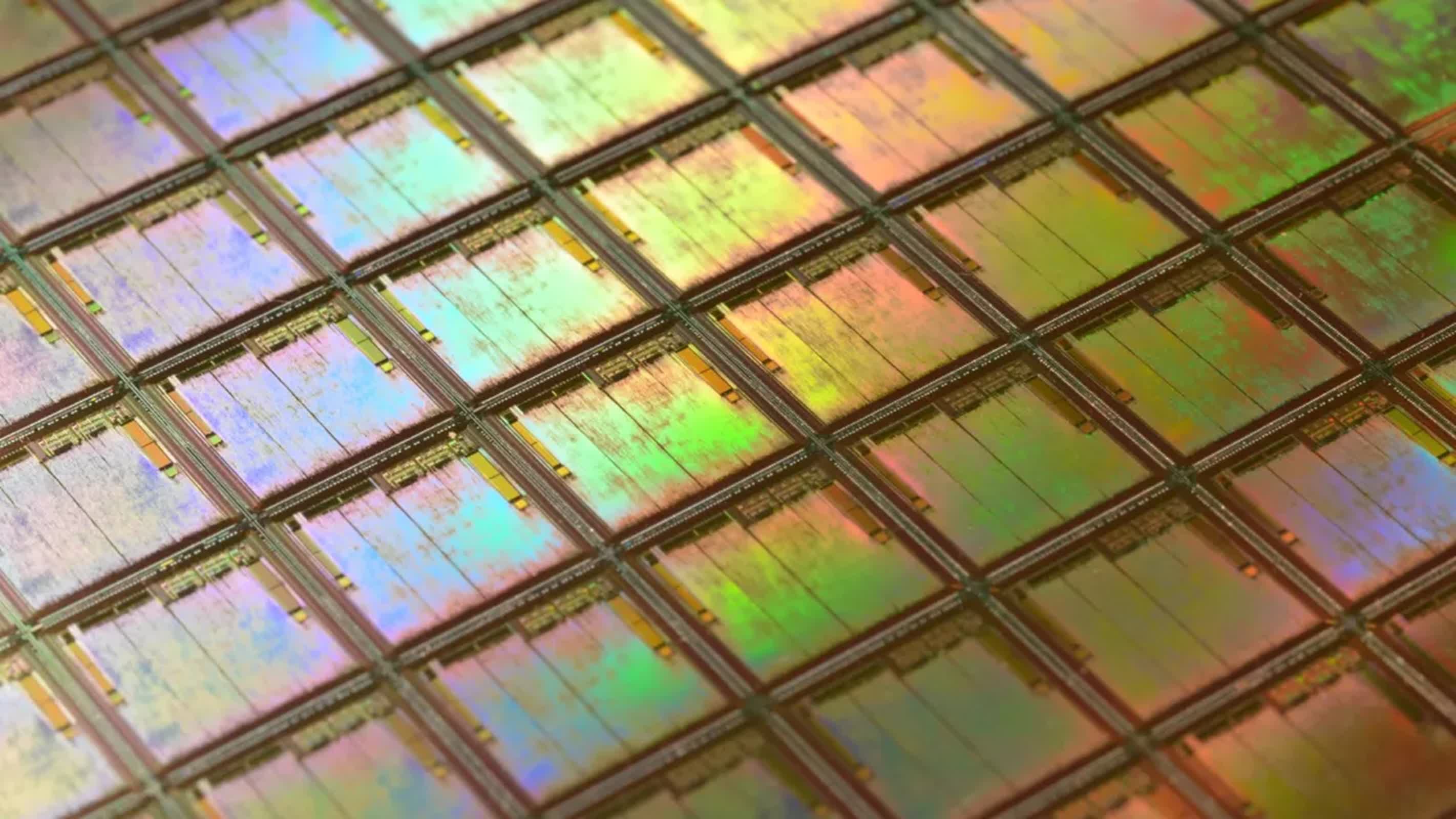

Regardless of this resilience, the earthquake might have affected between 10,000 to twenty,000 wafers at the moment in manufacturing. These wafers are vital for TSMC’s operations, significantly inside its superior fabrication vegetation situated within the Southern Taiwan Science Park, together with Fab 14 and Fab 18. These services are liable for producing state-of-the-art chips using N3 expertise for main purchasers akin to Apple and Intel.

Though inspections confirmed no harm to important infrastructure or utilities like electrical energy and water, the delicate technical gear inside these fabs might require recalibration resulting from vibrations from the earthquake and its aftershocks.

TSMC is predicted to replace its restoration timeline within the coming days.

The monetary implications of this occasion seem manageable for TSMC. Within the final quarter alone, the corporate processed over 3.4 million wafers, averaging round 37,000 wafers per day.

Consequently, regardless that 20,000 wafers could appear vital, they symbolize solely a small fraction of TSMC’s general output.

TSMC is predicted to renew full operations comparatively rapidly.

Historic context supplies additional reassurance; an identical earthquake in April 2024 resulted in losses estimated at $92 million however didn’t severely disrupt long-term operations or output. Actually, general instrument restoration in TSMC’s fabs reached greater than 70 % inside 10 hours of that earthquake.

Different semiconductor producers in Taiwan are additionally assessing their operations after implementing precautionary shutdowns, together with UMC and Innolux.

In the meantime, Taiwanese media report that TSMC suppliers have mobilized to get manufacturing working as quickly as doable. This mobilization is a part of TSMC’s long-standing enterprise threat administration system, which is designed to attenuate potential disruptions.

What simply occurred? Because the world’s main semiconductor producer, TSMC’s manufacturing halt following the 6.4-magnitude earthquake in Taiwan has triggered industry-wide concern. Its prospects are intently monitoring the corporate’s harm evaluation and potential manufacturing disruption, which might impression world chip provide chains.

The highly effective 6.4 magnitude earthquake that struck southern Taiwan on January 21 has led to a disruption in manufacturing at TSMC. Whereas there have been no reported fatalities, the tremor triggered appreciable harm all through the area, prompting the agency to implement fast security measures. TSMC evacuated employees from its central and southern manufacturing websites and quickly halted operations as a precautionary step.

Happily, preliminary inspections revealed that TSMC’s services largely withstood the quake with out main structural harm, because of their design, which accommodates seismic occasions of as much as magnitude 7.

Regardless of this resilience, the earthquake might have affected between 10,000 to twenty,000 wafers at the moment in manufacturing. These wafers are vital for TSMC’s operations, significantly inside its superior fabrication vegetation situated within the Southern Taiwan Science Park, together with Fab 14 and Fab 18. These services are liable for producing state-of-the-art chips using N3 expertise for main purchasers akin to Apple and Intel.

Though inspections confirmed no harm to important infrastructure or utilities like electrical energy and water, the delicate technical gear inside these fabs might require recalibration resulting from vibrations from the earthquake and its aftershocks.

TSMC is predicted to replace its restoration timeline within the coming days.

The monetary implications of this occasion seem manageable for TSMC. Within the final quarter alone, the corporate processed over 3.4 million wafers, averaging round 37,000 wafers per day.

Consequently, regardless that 20,000 wafers could appear vital, they symbolize solely a small fraction of TSMC’s general output.

TSMC is predicted to renew full operations comparatively rapidly.

Historic context supplies additional reassurance; an identical earthquake in April 2024 resulted in losses estimated at $92 million however didn’t severely disrupt long-term operations or output. Actually, general instrument restoration in TSMC’s fabs reached greater than 70 % inside 10 hours of that earthquake.

Different semiconductor producers in Taiwan are additionally assessing their operations after implementing precautionary shutdowns, together with UMC and Innolux.

In the meantime, Taiwanese media report that TSMC suppliers have mobilized to get manufacturing working as quickly as doable. This mobilization is a part of TSMC’s long-standing enterprise threat administration system, which is designed to attenuate potential disruptions.