Expertise Reporter

Sierra Area

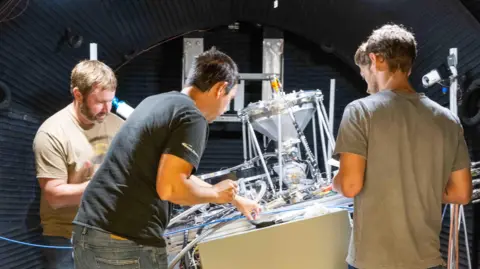

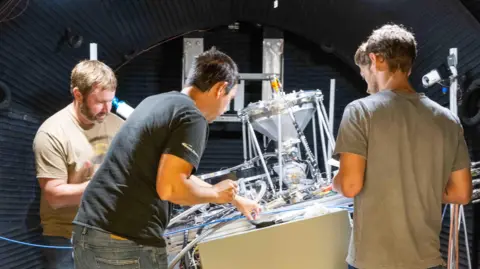

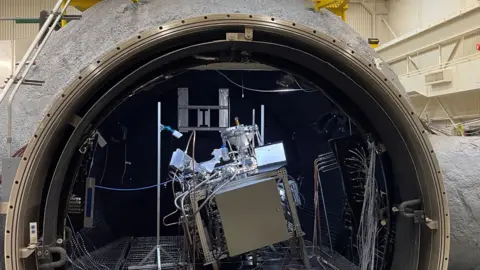

Sierra AreaInside an enormous sphere, the engineers pored over their tools. Earlier than them stood a silvery steel contraption swathed in vibrant wires – a field that they hope will someday make oxygen on the moon.

As soon as the staff vacated the sphere, the experiment started. The box-like machine was now ingesting small portions of a dusty regolith – a mix of mud and sharp grit with a chemical composition mimicking actual lunar soil.

Quickly, that regolith was gloop. A layer of it heated to temperatures above 1,650C. And, with the addition of some reactants, oxygen-containing molecules started to bubble out.

“We’ve examined every little thing we are able to on Earth now,” says Brant White, a program supervisor at Sierra Area, a personal firm. “The following step goes to the moon.”

Sierra Area’s experiment unfolded at Nasa’s Johnson Area Middle this summer time. It’s removed from the one such know-how that researchers are engaged on, as they develop techniques that would provide astronauts dwelling on a future lunar base.

These astronauts will want oxygen to breathe but additionally to make rocket gas for spacecraft which may launch from the moon and head to locations additional afield – together with Mars.

Lunar base inhabitants may also require steel and so they may even harvest this from the dusty gray particles that litters the lunar floor.

A lot relies on whether or not we are able to construct reactors capable of extract such sources successfully or not.

“It may save billions of {dollars} from mission prices,” says Mr White as he explains that the choice – bringing a lot of oxygen and spare steel to the moon from Earth – can be arduous and costly.

Sierra Area

Sierra AreaFortunately, the lunar regolith is stuffed with steel oxides. However whereas the science of extracting oxygen from steel oxides, for instance, is properly understood on Earth, doing this on the moon is way tougher. Not least due to the situations.

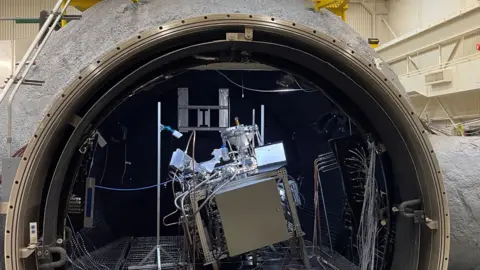

The large spherical chamber that hosted Sierra Area’s exams in July and August this 12 months induced a vacuum and in addition simulated lunar temperatures and pressures.

The corporate says it has had to enhance how the machine works over time in order that it could higher address the extraordinarily jagged, abrasive texture of the regolith itself. “It will get all over the place, wears out all types of mechanisms,” says Mr White.

And the one, essential, factor you could’t take a look at on Earth and even in orbit round our planet, is lunar gravity – which is roughly one sixth that of the Earth. It may not be till 2028 or later that Sierra Area can take a look at its system on the moon, utilizing actual regolith in low gravity situations.

NASA

NASAThe moon’s gravity might be an actual downside for some oxygen-extracting applied sciences until engineers design for it, says Paul Burke at Johns Hopkins College.

In April, he and colleagues printed a paper detailing the outcomes of pc simulations that confirmed how a distinct oxygen-extracting course of is perhaps hindered by the moon’s comparatively feeble gravitational pull. The method below investigation right here was molten regolith electrolysis, which includes utilizing electrical energy to separate lunar minerals containing oxygen, with a purpose to extract the oxygen instantly.

The issue is that such know-how works by forming bubbles of oxygen on the floor of electrodes deep inside the molten regolith itself. “It’s the consistency of, say, honey. It is extremely, very viscous,” says Dr Burke.

“These bubbles aren’t going to rise as quick – and may very well be delayed from detaching from the electrodes.”

There might be methods round this. One might be to vibrate the oxygen-making machine gadget, which could jiggle the bubbles free.

And additional-smooth electrodes may make it simpler for the oxygen bubbles to detach. Dr Burke and his colleagues are actually engaged on concepts like this.

Sierra Area’s know-how, a carbothermal course of, is completely different. Of their case, when oxygen-containing bubbles type within the regolith, they accomplish that freely, reasonably than on the floor of an electrode. It means there’s much less probability of them getting caught, says Mr White.

Stressing the worth of oxygen for future lunar expeditions, Dr Burke estimates that, per day, an astronaut would require the quantity of oxygen contained in roughly two or three kilograms of regolith, relying on that astronaut’s health and exercise ranges.

Nonetheless, a lunar base’s life help techniques would probably recycle oxygen breathed out by astronauts. If that’s the case, it wouldn’t be essential to course of fairly as a lot regolith simply to maintain the lunar residents alive.

The actual use case for oxygen-extracting applied sciences, provides Dr Burke, is in offering the oxidiser for rocket fuels, which may allow bold house exploration.

MIT and Shaan Jagani

MIT and Shaan JaganiClearly the extra sources that may be made on the moon the higher.

Sierra Area’s system does require the addition of some carbon, although the agency says it could recycle most of this after every oxygen-producing cycle.

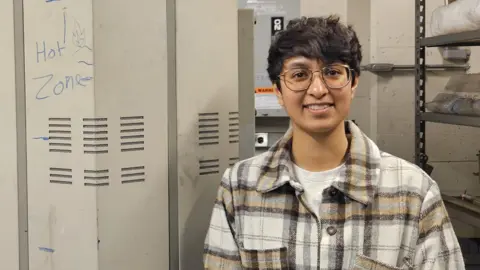

Together with colleagues, Palak Patel, a PhD pupil on the Massachusetts Institute of Expertise, got here up with an experimental molten regolith electrolysis system, for extracting oxygen and steel from the lunar soil.

“We’re actually it from the standpoint of, ‘Let’s attempt to minimise the variety of resupply missions’,” she says.

When designing their system, Ms Patel and her colleagues addressed the issue described by Dr Burke: that low gravity may impede the detachment of oxygen bubbles that type on electrodes. To counter this, they used a “sonicator”, which blasts the bubbles with sound waves with a purpose to dislodge them.

Ms Patel says that future resource-extracting machines on the moon may derive iron, titanium or lithium from regolith, for instance. These supplies may assist lunar-dwelling astronauts make 3D-printed spare components for his or her moon base or substitute parts for broken spacecraft.

The usefulness of lunar regolith doesn’t cease there. Ms Patel notes that, in separate experiments, she has melted simulated regolith into a tricky, darkish, glass-like materials.

She and colleagues labored out tips on how to flip this substance into robust, hole bricks, which might be helpful for constructing constructions on the moon – an imposing black monolith, say. Why not?

Expertise Reporter

Sierra Area

Sierra AreaInside an enormous sphere, the engineers pored over their tools. Earlier than them stood a silvery steel contraption swathed in vibrant wires – a field that they hope will someday make oxygen on the moon.

As soon as the staff vacated the sphere, the experiment started. The box-like machine was now ingesting small portions of a dusty regolith – a mix of mud and sharp grit with a chemical composition mimicking actual lunar soil.

Quickly, that regolith was gloop. A layer of it heated to temperatures above 1,650C. And, with the addition of some reactants, oxygen-containing molecules started to bubble out.

“We’ve examined every little thing we are able to on Earth now,” says Brant White, a program supervisor at Sierra Area, a personal firm. “The following step goes to the moon.”

Sierra Area’s experiment unfolded at Nasa’s Johnson Area Middle this summer time. It’s removed from the one such know-how that researchers are engaged on, as they develop techniques that would provide astronauts dwelling on a future lunar base.

These astronauts will want oxygen to breathe but additionally to make rocket gas for spacecraft which may launch from the moon and head to locations additional afield – together with Mars.

Lunar base inhabitants may also require steel and so they may even harvest this from the dusty gray particles that litters the lunar floor.

A lot relies on whether or not we are able to construct reactors capable of extract such sources successfully or not.

“It may save billions of {dollars} from mission prices,” says Mr White as he explains that the choice – bringing a lot of oxygen and spare steel to the moon from Earth – can be arduous and costly.

Sierra Area

Sierra AreaFortunately, the lunar regolith is stuffed with steel oxides. However whereas the science of extracting oxygen from steel oxides, for instance, is properly understood on Earth, doing this on the moon is way tougher. Not least due to the situations.

The large spherical chamber that hosted Sierra Area’s exams in July and August this 12 months induced a vacuum and in addition simulated lunar temperatures and pressures.

The corporate says it has had to enhance how the machine works over time in order that it could higher address the extraordinarily jagged, abrasive texture of the regolith itself. “It will get all over the place, wears out all types of mechanisms,” says Mr White.

And the one, essential, factor you could’t take a look at on Earth and even in orbit round our planet, is lunar gravity – which is roughly one sixth that of the Earth. It may not be till 2028 or later that Sierra Area can take a look at its system on the moon, utilizing actual regolith in low gravity situations.

NASA

NASAThe moon’s gravity might be an actual downside for some oxygen-extracting applied sciences until engineers design for it, says Paul Burke at Johns Hopkins College.

In April, he and colleagues printed a paper detailing the outcomes of pc simulations that confirmed how a distinct oxygen-extracting course of is perhaps hindered by the moon’s comparatively feeble gravitational pull. The method below investigation right here was molten regolith electrolysis, which includes utilizing electrical energy to separate lunar minerals containing oxygen, with a purpose to extract the oxygen instantly.

The issue is that such know-how works by forming bubbles of oxygen on the floor of electrodes deep inside the molten regolith itself. “It’s the consistency of, say, honey. It is extremely, very viscous,” says Dr Burke.

“These bubbles aren’t going to rise as quick – and may very well be delayed from detaching from the electrodes.”

There might be methods round this. One might be to vibrate the oxygen-making machine gadget, which could jiggle the bubbles free.

And additional-smooth electrodes may make it simpler for the oxygen bubbles to detach. Dr Burke and his colleagues are actually engaged on concepts like this.

Sierra Area’s know-how, a carbothermal course of, is completely different. Of their case, when oxygen-containing bubbles type within the regolith, they accomplish that freely, reasonably than on the floor of an electrode. It means there’s much less probability of them getting caught, says Mr White.

Stressing the worth of oxygen for future lunar expeditions, Dr Burke estimates that, per day, an astronaut would require the quantity of oxygen contained in roughly two or three kilograms of regolith, relying on that astronaut’s health and exercise ranges.

Nonetheless, a lunar base’s life help techniques would probably recycle oxygen breathed out by astronauts. If that’s the case, it wouldn’t be essential to course of fairly as a lot regolith simply to maintain the lunar residents alive.

The actual use case for oxygen-extracting applied sciences, provides Dr Burke, is in offering the oxidiser for rocket fuels, which may allow bold house exploration.

MIT and Shaan Jagani

MIT and Shaan JaganiClearly the extra sources that may be made on the moon the higher.

Sierra Area’s system does require the addition of some carbon, although the agency says it could recycle most of this after every oxygen-producing cycle.

Together with colleagues, Palak Patel, a PhD pupil on the Massachusetts Institute of Expertise, got here up with an experimental molten regolith electrolysis system, for extracting oxygen and steel from the lunar soil.

“We’re actually it from the standpoint of, ‘Let’s attempt to minimise the variety of resupply missions’,” she says.

When designing their system, Ms Patel and her colleagues addressed the issue described by Dr Burke: that low gravity may impede the detachment of oxygen bubbles that type on electrodes. To counter this, they used a “sonicator”, which blasts the bubbles with sound waves with a purpose to dislodge them.

Ms Patel says that future resource-extracting machines on the moon may derive iron, titanium or lithium from regolith, for instance. These supplies may assist lunar-dwelling astronauts make 3D-printed spare components for his or her moon base or substitute parts for broken spacecraft.

The usefulness of lunar regolith doesn’t cease there. Ms Patel notes that, in separate experiments, she has melted simulated regolith into a tricky, darkish, glass-like materials.

She and colleagues labored out tips on how to flip this substance into robust, hole bricks, which might be helpful for constructing constructions on the moon – an imposing black monolith, say. Why not?