Infineon

Proper now, the vacation spot for the circuit board inside a tool you not want is nearly definitely a big shredder, and that is the best-case state of affairs.

Most gadgets that do not have resale or reuse worth find yourself going into the shredder—in the event that they even make it into the e-waste stream. After their batteries are (hopefully eliminated, the shredded boards cross by way of magnets, water, and incineration, to drag particular minerals and metals out of the boards. The woven fiberglass and epoxy resin the boards had been constituted of aren’t price a lot after they’re sliced up, so that they find yourself as waste. That waste is put in landfills, burned, or generally simply stockpiled.

That is why, even when it is nonetheless in its earliest levels, one thing just like the Soluboard sounds so promising. UK-based Jiva Supplies makes printed circuit boards (PCBs) from pure fibers encased in a non-toxic polymer that dissolves in sizzling water. That leaves behind entire parts beforehand soldered onto the board, which needs to be simpler to get better.

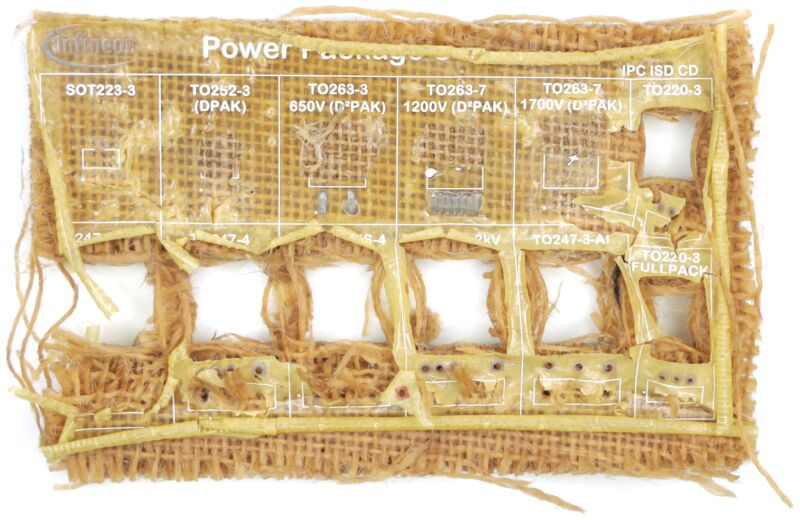

Here is the “earlier than” pic of an Infineon board assembled on Jiva Applied sciences’ water-soluble PCB.

InfineonAnd here is the “After,” exhibiting a neat elimination of parts and an actual parking-lot-of-a-Phish-concert vibe.

Infineon

It is price noting, particularly for the clumsy amongst us, that Soluboard’s PCBs aren’t more likely to be dissolved by an errant Americano. Soluboards require no less than half-hour of immersion in roughly 90° Celsius water earlier than delamination begins, the corporate’s CEO instructed The Register.

Infineon, Germany’s largest semiconductor producer and maker of parts in automobiles, Raspberry Pis, and industrial tools, has produced demo boards utilizing Soluboard’s tech. The corporate says it is also researching the reusability of “discrete energy gadgets on the finish of their service life,” which might promote round reuse and scale back the carbon price of manufacturing new gadgets. Infineon estimates that changing conventional FR-4 PCBs with Soluboard would lead to a 60 p.c discount of carbon emissions, or roughly 10.5 kg (23 kilos) of carbon and 620 g (21 ounces) of plastic per sq. meter of PCB produced. That provides up, given the 18 billion sq. meters of PCBS manufactured every year, in accordance with Jiva.

Soluboards have had no less than one outing within the US, being the core of an “Ecofriendly Mouse” design created by College of Washington researchers in collaboration with Microsoft. That research discovered comparable knowledge transmission for embedded chips. Chips recovered after board dissolution had been baked in an oven to take away moisture, then “reused with no indicators of efficiency loss.”

Soluboards will want much more testing within the wild earlier than widespread use. And electronics recycling, an business with notably tight margins, could not discover as a lot worth in recovering chips from soluble boards because the rosiest state of affairs may counsel. However any potential development in electronics that makes use of much less plastic, and makes issues a little bit simpler to interrupt down, is price a better look.